Cranes are one of the most valuable pieces of equipment in many industries, making it possible to lift heavy loads. But do you know that one of the hazardous encounters in operating cranes is the occurrence of a two-blocking?

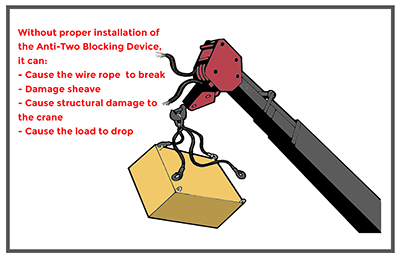

So, what is two-blocking? Two blocking happens when the uppermost hoist line component (the load block, hook block, overhaul ball, etc.) touches the upper block, boom tip, or a similar part. If this happens, the tension on the line will increase, which results in falling loads or crane components. According to OSHA, 1 in 1,000 maritime crane operators will suffer fatal injuries from such accidents.

How can we prevent two blocking?

The best way to prevent two blocking is by installing a device called the Anti-Two blocking device. Made mandatory by OSHA and ASME standards, it assists crane operators with its built-in sensors to avoid such mishaps. ASME B30.5 Mobile and Locomotive Cranes state:

(a) Telescopic boom cranes shall be equipped with an anti-two block device or a two-block damage prevention feature for all points of two-blocking…

(b) Lattice boom cranes shall be equipped with an anti-two block device or a two-block warning feature that functions for all points of two-blocking.

Having an anti-two blocking device will ensure the safety of workers, which gives them a sense of security and, in turn, leads to increased productivity and efficiency at work. Using this device ensures the safety of lift operations and loads are also transported securely without property damage.

References: OSHA 1926.1416 Operational Aids, ASME B30.5 Mobile and Locomotive Crane